Polycyclic aromatic hydrocarbons (PAHs) are prevalent throughout our lives in everyday household use, such as candles, cooking, smoking and car emissions to urban waste streams and industrial processes. Within manufacturing facilities, there must be an integral understanding of the contaminants created as part of production waste, whilst responsibly tackling PAHs alongside VOCs and PFAS as part of the operational journey.

What are Polyaromatic Hydrocarbons?

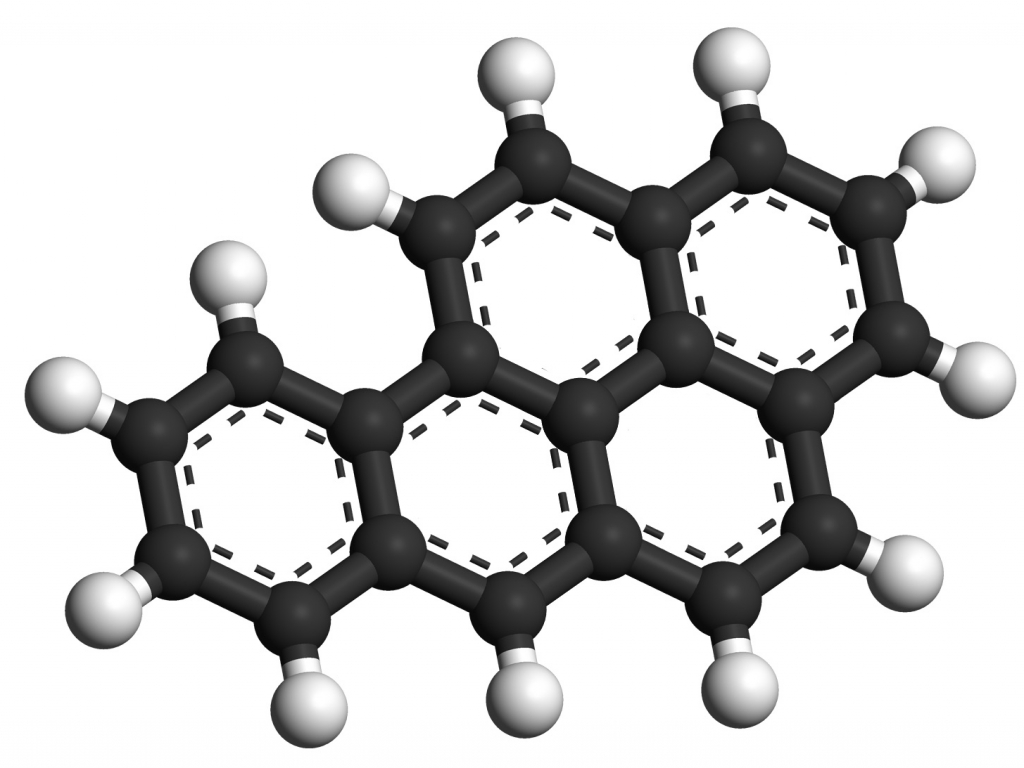

There are generally 16 prominent PAHs deemed as high-priority pollutants, with common ones such as benz[a]anthracene (BaA), benzo[a]pyrene (BaP) and chrysene, typically produced through incomplete combustion of organic material. PAHs are naturally derived from reactions generated from wildfires or volcanoes that forms a molecular structure containing two or more fused aromatic rings. PFAS pollutants are rightfully a critical area of concern, yet polyaromatic hydrocarbons and volatile organic compounds (VOCs) are just as essential for removal, contributing to the contamination of air, water and soil.

The Importance of PAH Removal

Polyaromatic hydrocarbons are known to cause several health conditions, notably for their adsorption properties into the skin and lungs. Recognised as a carcinogen, with mutagenic properties, the long-term effects have been well documented to cause severe harm.

PAHs are toxic to wildlife, affecting soil and water sources from consistent waste streams. This can cause inherent problems for the food chain through the consumption of sources such as seafood, which is why PAHs are recognised and strictly regulated by the European Food Safety Authority.

Within any manufacturing sector, the vital question is how to be more sustainable, handle waste and find economical solutions. Critical areas of contamination are created from wet and dry depositions, such as process water/wastewater and air pollution. Rainfall run-off from urban sites can take these contaminants and deposit them across various sediments and water sources.

The Life Cycle of Contaminants in Manufacturing

Contaminants stem from several sources, affecting individual areas of environmental concern across various stages of the journey. The typical manufacturing processes generate waste in the following life cycles:

- Industrial and manufacturing sectors produce process and wastewater through the production of products and services.

- Wastewater goes through treatment to reduce harmful pollutants, however, PAHs can still be released into water sources at this point with incorrect treatment procedures.

- Contaminants in the atmosphere are formed from different fuel combustions and harmful gases created during manufacturing processes.

- Contaminants break down within the atmosphere, undergoing chemical reactions with sunlight and other elements.

- Run-off from rainfall and wind carries PAH, VOC and PFAS contaminants, which are deposited in natural sources over a period of time.

- Large molecular contaminants, that are less water-soluble, begin to settle on the beds of still bodies of water.

- Contaminated groundwater and reservoirs are placed back into the water system as drinking water or part of manufacturing processes, renewing the lifecycle.

Although this is not an exhaustive list of how contaminants derive from manufacturing, it showcases the longevity and sustained economic impact when improper treatment is used.

Purification Solutions of PAH and VOCs

Hydrocarbons, VOCs and PFAS contaminants affect businesses and industrial sites every day. With strict legislation on environmental impact, it’s crucial that various industries tackle harmful waste streams that are produced. Activated carbon plays an essential role in the purification of both water and air, removing a wide range of contaminants including PAHs, VOCs and PFAS group chemicals.

Our own FiltraCarb® range showcases the market-leading performance and innovative benefits for effective contaminant removal. Filtracarb® SK1® is considered to be the ‘industry standard’ for one key PAH removal application, namely from edible oils, with laboratory results confirming a >99% efficiency for the removal of PAH compounds.

In addition to a range of premium FiltraCarb® activated carbons, Puragen Activated Carbons also supplies carbon mobile filters for both liquid and air purification, suitable to withstand a spectrum of hydrocarbons and various other contaminants. We ensure that activated carbon treatment can be seamlessly integrated within your company operations, or run separately alongside existing processes.

Industries that Produce Hydrocarbons

PAHs are prominent within industrial processes and everyday products, particularly of material made of plastic or part of an incomplete burning process. However, the most prevalent source of PAHs stem from:

- Coal and steel industries

- Engineering and manufacturing

- Petroleum refineries

- Transportation

- Bitumen and asphalt production

- Incineration

- Chemical and pharmaceuticals

Removing harmful contaminants is fundamental for manufacturing sectors, with stringent legislation against PAH contaminants, industries must instil the mindset of creating healthier environments and responsible waste treatment.

Other harmful contaminants that activated carbon removes

Activated carbon removes a diverse list of contaminants from water and air phases. Along with PAH, VOCs, and PFAS, carbon is effective at eliminating pesticides, herbicides, pharmaceuticals, chlorine, and harmful airborne gases or odours. Since PAHs can also be naturally derived, activated carbon also plays an essential role in the removal of contaminants in edible oils, ensuring food-grade safe quality.

Puragen Purification Solutions

Here at Puragen, we have a team of experts ready to help industries find sustainable purification solutions. Formulated from carbon-rich organic materials such as coal, coconut shell and wood, activated carbon offers an economical and environmentally conscious removal of PAH and other contaminants. Carbon delivers excellent results, with the ability to reactivate spent carbons at our Green Apple-awarded facility.

For further guidance about activated carbon services and contaminant removal, please get in touch with our team today.