Exploring the Applications and Benefits of Activated Carbon

A remarkable purification agent, activated carbon finds itself at the forefront of environmental protection and industrial processes. Its versatile nature, coupled with advanced adsorption properties, makes it indispensable across various sectors and industries.

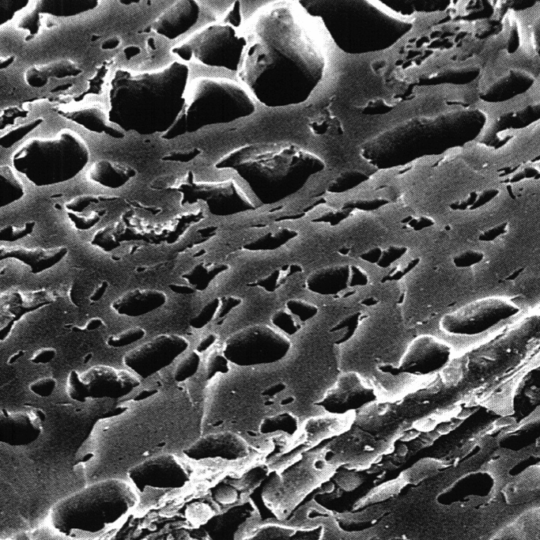

Activated carbon, derived from carbon-rich materials like wood, coconut shells, and coal, boasts a highly porous structure. This structure provides an extensive surface area, enabling it to capture a wide array of contaminants, including volatile organic compounds (VOCs) and water-based pollutants. Its versatility underscores its critical role in enhancing environmental quality and operational efficiency across diverse sectors.

Benefits of Activated Carbon:

Environmental Protection

Activated carbon aids in environmental protection by eliminating toxic and harmful compounds, thereby mitigating pollution and preserving ecosystems.

Public Health

Cleaner air and water, facilitated by activated carbon, contribute to improved public health by reducing exposure to pollutants and contaminants.

Industrial Efficiency

Activated carbon enhances industrial process efficiency by removing impurities and ensuring product quality, thereby reducing production costs and minimising downtime.

Cost-effectiveness and Sustainability

The reactivation and reuse of spent activated carbon offer a cost-effective and sustainable purification solution, minimising waste and conserving natural resources. The ‘carbon footprint’ saving association with this recycling of spent activated carbon is over 90%, thanks to our award-winning REACT-Sys® technology.

Activated Carbon Applications

Air and Gas Purification

Activated carbon is extensively used in air and gas purification processes due to its high surface area and exceptional adsorption properties. In this application, activated carbon removes pollutants and contaminants from gases, including volatile organic compounds (VOCs), odours, and airborne toxins. By adsorbing these pollutants onto its surface, activated carbon effectively purifies the air and gas streams, resulting in cleaner and safer environments. Industries such as automotive, manufacturing, and HVAC systems rely on activated carbon for air purification to comply with environmental regulations and improve indoor air quality.

Biogas & Biomethane Purification

Activated carbon plays a crucial role in the purification of biogas and biomethane, which are produced from organic waste materials through anaerobic digestion. During this process, impurities such as hydrogen sulfide (H2S), ammonia (NH3), siloxanes and other volatile organic compounds (VOCs) are generated, which can degrade the quality of biogas and biomethane. Activated carbon adsorption efficiently removes these impurities, ensuring the purity and stability of the gas for various applications such as electricity generation, heating, and transportation fuels. The use of activated carbon in biogas purification enhances the sustainability of renewable energy production by facilitating the utilisation of biogas as a clean energy source.

Consumer Products

Activated carbon is crucial for purifying and ensuring safety in consumer products. It eliminates impurities, odours, and contaminants, enhancing product quality. From air purifiers to toothpaste, it maintains product integrity and meets consumer expectations. Its uses extend to food packaging for shelf-life extension and odour control products. As health and environmental concerns rise, activated carbon’s incorporation in consumer goods grows, providing reliable purification and safety enhancements.

Chemicals & Pharmaceuticals

In the chemicals and pharmaceuticals industry, activated carbon finds widespread application in purification processes, including the removal of impurities, colourants, and contaminants from chemical intermediates, solvents, and pharmaceutical products. Activated carbon’s high surface area and adsorption capacity make it an effective adsorbent for purification applications, ensuring the quality and purity of chemical and pharmaceutical products. Additionally, activated carbon is employed in wastewater treatment processes to remove organic pollutants and trace contaminants, contributing to environmental protection and regulatory compliance within the industry.

Engineering and Manufacturing

Activated carbon plays a pivotal role in engineering and manufacturing, ensuring operational efficiency and environmental safety. It’s widely used across industries like automotive, aerospace, electronics, and textiles for diverse applications, from air purification to wastewater treatment, including the removal of PFAS-group chemicals from effluent streams. Additionally, it aids in the purification of industrial gases and maintenance of heating systems and turbines. Overall, activated carbon’s versatility supports sustainable practices and product integrity in various engineering sectors.

Edible Oil Purification

Activated carbon is commonly utilised in the purification of edible oils to remove impurities, unwanted flavours, colours, and odours. During the refining process, activated carbon adsorbs contaminants such as chlorophyll, free fatty acids, and other organic compounds, resulting in clearer, flavour-neutral, and odour-free edible oils. This purification process enhances the quality and shelf life of edible oils while meeting regulatory standards for food safety and consumer satisfaction. Activated carbon’s efficient adsorption capabilities make it an indispensable tool in the edible oil industry for achieving desired product characteristics and maintaining product integrity.

Food & Beverage

Activated carbon plays a vital role in the food and beverage industry, where it is employed for various purification and processing applications. In food processing, activated carbon is utilised for decolourisation, deodorisation, and purification of food ingredients such as sugar, gelatin, and fruit juices. Moreover, activated carbon is utilised in beverage production for the removal of contaminants, off-flavours, and undesirable compounds from water, alcoholic beverages and soft drinks, ensuring product quality and consumer satisfaction. In the brewery industry, activated carbon is used for the dechlorination of process water, to improve the beer’s taste, and for CO2 purification. The use of activated carbon in the food and beverage industry contributes to the production of safer, higher-quality products that meet stringent regulatory standards and consumer expectations.

Flue Gas Treatment

Activated carbon is utilised in flue gas treatment systems to mitigate emissions of pollutants such as mercury and volatile organic compounds (VOCs, including dioxins and furans) from industrial processes and combustion sources. By adsorbing these pollutants onto its surface, activated carbon effectively captures and removes them from flue gas streams, thereby reducing environmental pollution and complying with increasingly stringent emissions regulations. Flue gas treatment with activated carbon is employed in various industries, including power generation, cement production, steel manufacturing and waste incineration, to minimise environmental impact and improve air quality in surrounding areas. The new EU BREF regulations, that came into force in December 2023, mean that energy-from-waste (EfW) facilities must achieve much lower mercury and dioxin/furan emissions, and Puragen is at the forefront of this sector with its FiltraCarb® FGT® range of products.

Gold Recovery

Activated carbon plays a critical role in the recovery of gold from cyanide leach solutions in the gold mining industry. Through the process of carbon-in-pulp (CIP) or carbon-in-leach (CIL), activated carbon adsorbs the gold complex from the cyanide solution, allowing for efficient extraction and recovery of gold particles. The high surface area and adsorption capacity of activated carbon make it an ideal adsorbent for gold recovery applications, enabling high gold yields and minimal gold losses during the extraction process. Activated carbon regeneration processes allow for the reuse of spent carbon, making gold recovery operations more cost-effective and sustainable.

Water Treatment

Activated carbon is widely employed in water treatment processes for the removal of organic contaminants, disinfection by-products, taste and odour compounds, colour-forming molecules and trace pollutants from drinking water and wastewater. These contaminants include pesticides, herbicides, pharmaceuticals and other persistent organic pollutants (POPs) including PFAS-group ‘forever chemicals’. In water treatment applications, activated carbon acts as a versatile adsorbent, effectively removing a wide range of contaminants through physical adsorption. Whether in granular (GAC) or powdered (PAC) form, activated carbon enhances water quality by reducing pollutants, improving taste and odour, and ensuring compliance with drinking water standards and regulations. Water treatment facilities, municipalities, and industries rely on activated carbon as a crucial component of their water purification strategies to provide clean and safe drinking water to communities and protect aquatic ecosystems.

Why Choose Puragen for Purification Solutions

With a comprehensive product range, including coal, coconut shell, and wood-based activated carbons, sold under the FiltraCarb® brand name, Puragen caters to diverse purification needs across industries.

Some of the many reasons why you should choose Puragen include:

Commitment to Innovation

Our active research and development programme ensures continuous innovation in carbon materials and technologies.

State-of-the-Art Reactivation Facility

Puragen’s award-winning REACT-Sys® thermal reactivation process recycles spent carbons in an eco-conscious manner, minimising waste and encouraging circular resource use.

Mobile Carbon Filters

We offer a broad range of Clean-Flo® mobile carbon filters for liquid (AquaSorber®) and gas phase (VOCSorber®) applications, providing flexible and efficient purification solutions.

Ongoing Support

With a dedicated Site Services team, Puragen facilitate the installation of carbon filters and the removal/changeout of spent media, ensuring seamless operations for its clients.

Extensive Industry Expertise

Backed by an experienced sales and marketing team, we provide knowledgeable support and efficient service to our clients, ensuring their purification requirements are met effectively.

Fully Accredited

Puragen adheres to the highest quality, environmental, health, and safety standards, holding full accreditation to ISO 9001, ISO 14001, ISO 45001, and legislative standards such as EU and UK REACH.

Contact Puragen for Purification Solutions Today

Activated carbon serves as a cornerstone in environmental and industrial purification. Whether it’s air and water purification, industrial processes, or biogas treatment, activated carbon continues to revolutionise the way we approach purification challenges, ensuring a cleaner and healthier future for generations to come.

For further information and guidance regarding our activated carbon solutions, get in touch with our experts at Puragen today.