What is Activated Carbon?

Activated carbon, also known as activated charcoal, active carbon, or active coal, is a highly porous form of carbon with an exceptionally large surface area and a complex network of microscopic pores.

These unique properties make it a powerful material for removing contaminants from liquids and gases, ensuring cleaner air, water and industrial process streams.

Where does activated carbon come from?

Activated carbon is derived from carbon-rich raw materials, including coal, coconut shells and wood. These materials undergo a specialised activation process to create carbon with precise absorption characteristics for specific applications.

At Puragen, we continuously develop new carbon sources to improve performance, efficiency, and sustainability across air, water, and energy purification.

How is carbon activated for purification?

The activation process generally begins with charring raw materials in the absence of oxygen, to remove volatile compounds and leave behind a carbon-rich structure. The material is then exposed to high-temperature steam or chemicals to open up a vast network of internal pores.

This process dramatically increases the surface area, enabling activated carbon to capture contaminants through adsorption, making it highly effective for purification applications.

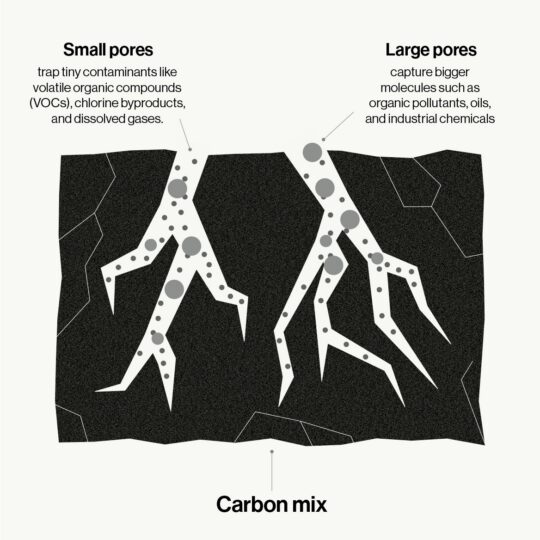

How does activated carbon work?

Activated carbon works through adsorption, a process where pollutants stick to its porous surface. Each gram of activated carbon can have a surface area of over 1,000 square meters, made up of microscopic pores of varying size, quantity and ratio, which trap impurities and unwanted molecules from streams of air, gas and liquids.

This makes activated carbon highly suited for applications like water treatment, industrial air filtration, biogas purification and environmental remediation.

What are the different forms of activated carbon?

Activated carbon comes in various forms, each designed for specific industrial purification needs.

Granular Activated Carbon (GAC)

GAC consists of irregularly shaped granules suited for continuous flow filtration in water treatment and air purification, in deep-bed adsorbers. It provides efficient adsorption while minimising pressure drop, making it highly suited for large-scale operations, particularly in municipal water treatment and industrial VOC removal. Different sizes of granules are available, with smaller sizes generally being used for liquid phase applications, while larger GAC grades are popular for gas phase systems.

Powdered Activated Carbon (PAC)

PAC has fine particles with a high surface area that offer fast adsorption of high volumes of impurities. It’s ideal for batch processes and situations where rapid adsorption is important, such as emergency water treatment or chemical spills response.

Extruded Activated Carbon Pellets

Extruded carbon is formed into uniform cylindrical pellets that are hard, durable and produce low levels of dust. The uniform shape makes them easy to handle, and particularly suited for gas-phase applications, such as air purification, VOC control and odor removal in industrial settings such as food production and waste processing.

Solid Carbon Monoliths

Solid Carbon Monoliths are a newer development in the field of activated carbon, offering a rigid structure with interconnected pores. They are particularly effective in applications requiring high flow rates and low-pressure drops, such as industrial exhaust treatment.

Industrial applications of

activated carbon

Activated carbon is used across various industries to purify air, gas, water, and biogas, ensuring compliance, efficiency, and sustainability.

Air & Gas Purification

VOCs and odor removal and flue gas treatment, for industrial air filtration and emissions

Water & Liquid Filtration

Drinking water treatment and industrial process water purification to remove PFAS, chlorine, pesticides, and disinfection byproducts, as well as other liquid phase purification such as applications in the beverage and chemicals industries.

Biogas Purification

Anaerobic digestion sites, landfill gas and wastewater biogas, to improve biogas quality, remove contaminants and protect CHP engines and facilitate biomethane gas-to-grid operations.

Our Capabilities

To deliver the best possible filtration solutions for every customer, Puragen takes a long term partnership approach, we can manage and support each and every stage of the journey, and are committed to innovation to improve everything we do.

Expertise & Analytics

Our award winning chemists, materials scientists and engineers use leading lab facilities and analytics to derive and support precise technical solutions for each customer requirement.

Carbon Engineering

We supply a comprehensive range of carbons tailored to specific applications. We also enhance the performance of our carbon for specific processes via impregnation and precise particle sizing.

Fixed Filter Services

We can manage as much of the carbon lifecycle as each customer requires, from supply, carbon exchange and reactivation to system maintenance and optimisation.

Mobile Filtration

We operate a growing mobile filter fleet to deliver scalable, plug and play filters to customers, with maximum flexibility, minimal downtime, and no on-site waste handling.

Reactivation

We operate one of the most advanced closed-loop carbon reactivation networks in Europe to deliver efficient filtration, traceability and environmental benefits.

Integrated Logistics

Our processing and logistics hubs deliver to and support each customer’s needs across our full range of products and services.